Stainless Steel Side Exhaust

One problem with the performance of this little Diesel engine in a l300 is the stock exhaust. It is long and just 2″ crushed bent piping with a standard muffler. Obviously the back pressure is high and it does not really support the breathing of the engine. Therefore using larger diameter, better bent piping and a free-flow muffler should improve the situation.

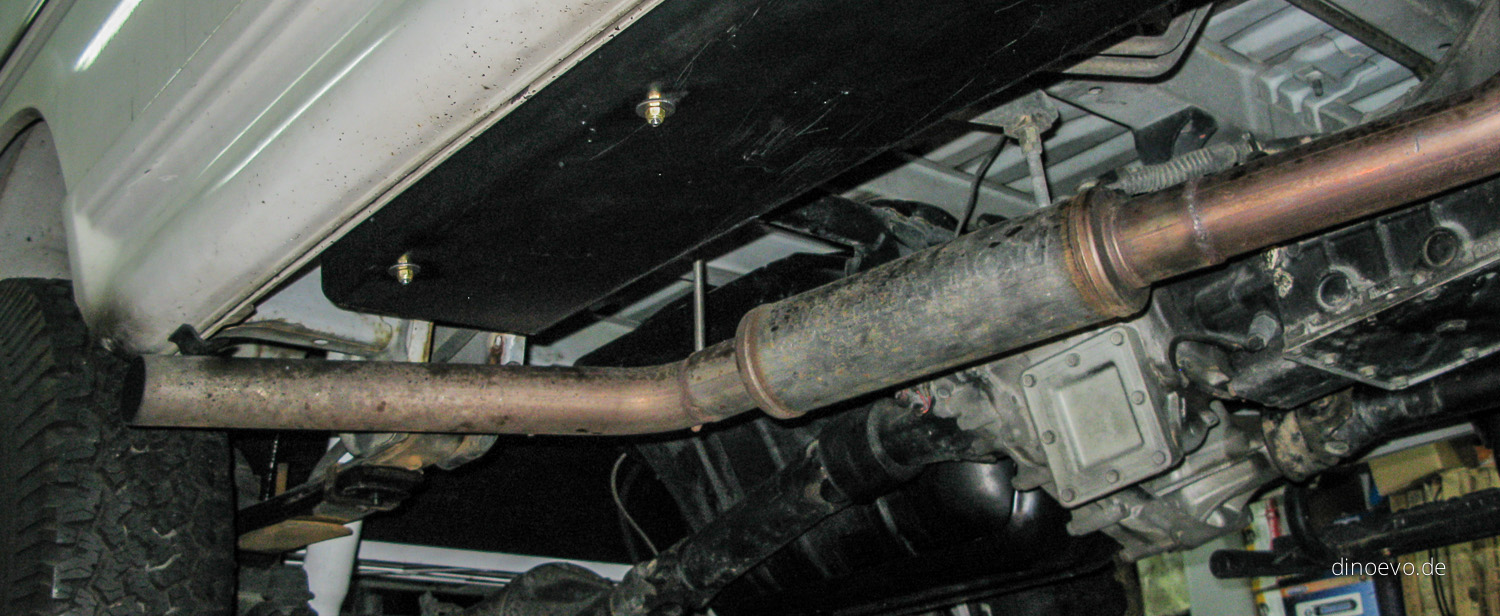

The manifold and the down pipe should be changed too, to have no bottleneck in the exhaust system. Unfortunately the muffler shop could not find the right parts. That’s why our exhaust starts actually with the stock down pipe where the new larger stainless steel pipe is welded to. No ideal, but better than nothing.

I bought one of the smallest round, stainless Magnaflow mufflers* I could find and took it to a local muffler shop to get the proper stainless steel piping and hangers.

To save space for future modifications (hot water tank, additional Diesel tank) as well as keeping the exhaust as short as possible we went with an side exit right in front of the driver side rear wheel.

Update:

I was not very happy with the crappy work from Quite Muffler on Kingsway. They are neither very friendly nor have they done a good job. Stay away from them!

So I sold the exhaust again and was back to the drawing board. After a few more calls with the local Hot Rod community I found Muffler Tech in Port Coquitlam. They had all the parts in stock and had no problem fabricating the tubes. Also it turned out it is the only place in Western Canada which actually does mandrel bending. Great!

After a day I picked up the van with an very well designed exhaust how I had it in mind.